Mention the word dunnage to people outside of the packaging and logistics industries and you’re likely to get a blank stare. Do a little digging and you’ll find the word is believed to be a derivative of a German term “dünne twige” meaning brushwood. That kind of makes sense as lumber is often used for dunnage but no one has proved the linguistic connection.

SCHAEFGUARD® custom reusable dunnage

So just what exactly is dunnage? Dunnage is a form of transport packaging with the sole purpose of filling a void. Traditionally, inexpensive or waste materials were used to secure cargo, both inside a container like a box or crate and between containers, during transportation via ship, truck, or train to prevent damage caused by shifting, sustained vibrations or impacts. Today, however, materials used in dunnage are increasingly sophisticated and include lumber, steel, plastic, corrugated and paper as well as bubble wrap, foam board and buns, and air pillows.

The logistics and supply chain industry looked at dunnage as a “one and done” low-cost commodity that was shuffled off to a landfill after a single-use. As the volume of goods moving through global supply chains has ballooned so, too, has waste.

And it’s simply not sustainable.

Moving from Expendable to Reusable Dunnage Solutions

Businesses deploying transport packaging for product distribution are evaluating how their dunnage can move away from cheap and disposable dunnage to durable and high-performing reusable dunnage solutions that close the loop on waste prevention. It’s not an easy transition. Moving dunnage from a linear to circular model is much like asking the Titanic to make a U-turn. Still, there are pioneers and leaders in reusable dunnage, most notably the automotive industry, and conversations around and interest in adopting reusable solutions are growing.

For member companies of the Reusable Packaging Association (RPA), there are several major drivers of the reusable dunnage movement. They are:

ORBIShield® custom reusable dunnage

Rising raw materials costs

The prices of dunnage staples have increased significantly over the last year. According to the National Association of Homebuilders, lumber is up 300% since April 2020. The Wall Street Journal reports corrugated has jumped $50 per ton. Resin prices continue to climb amid scarce supplies, escalating energy and feedstock costs, and COVID-19 and weather-related disruptions.

Rick Sasse, custom packaging manager for Vantage Plastics, says pricing volatility of traditional dunnage materials has increased interest in reusable packaging. “Without a doubt, the cost of single-use materials like lumber and corrugated has piqued interest to switch to reusables. Customers I talk to are looking for alternative solutions such as the thermoformed plastic dunnage that can be reused multiple times and drive down their spend.”

Greater awareness of the value of reusables

A one-size-fits-most approach to expendable dunnage may seem like an acceptable approach but for manufacturers of Class A parts, it often means sub-par protection. Jay Amatangelo, director of business development for Amatech, a supplier of custom reusable dunnage, says the demand for reusable dunnage has definitely been impacted by increased awareness on the part of customers. Education on materials, customization, and lifespan of reusable versus expendable dunnage is central to their marketing efforts.

“Companies are very interested when they understand the benefits of custom reusable dunnage. At Amatech, we can get very detailed on how a specific part is protected and also how it is presented in the pack so that when it arrives at the assembly line, it’s ready to pick and place. While it may cost more on the front end, our reusable dunnage can be used for up to five years so the ROI on the package, reduction in damage, and landfill avoidance make a compelling argument for reusable dunnage,” Amatangelo explains.

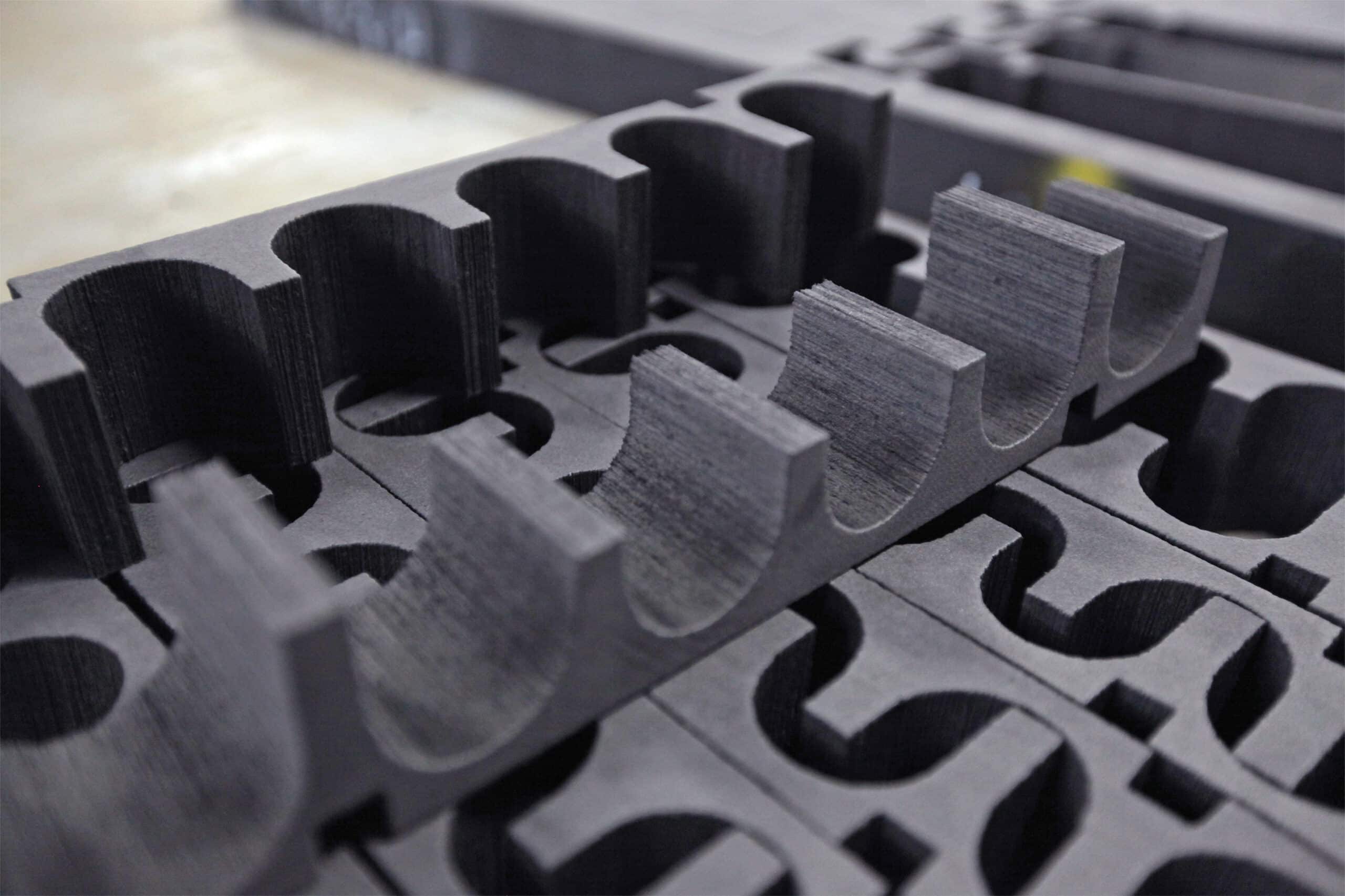

Assorted reusable dunnage solutions from Amatech

Government pressure

According to Eva de la Torre, business development manager for Corplex, Europe is not seeing the same raw material price increases as North America. Instead, the European Union is using regulations and taxes to discourage single-use packaging and encourage adoption of reusable dunnage. “The European Union (EU) passed a law in January requiring wooden boxes, crates, pallets, and dunnage to be sanitized after traveling between EU nations and the United Kingdom. This is driving adoption of easier to maintain plastic alternatives,” she says.

“There are also taxes on non-recycled packaging that also incentivize companies to move to reusable and recyclable plastic dunnage such as our Correx® line that is reusable for upwards of ten years and recyclable at end of life. Taxes are avoided because many plastics are infinitely recyclable with no loss of performance,” she adds.

The earliest adopter of reusable dunnage? The automotive industry

Overwhelmingly, the automotive industry is the number one customer of reusable dunnage in dividers and partitions. There are several things that make this possible. First, the automotive industry has a clearly defined supply chain where multiple suppliers provide parts to an automotive brand, shipping parts that require protection to assembly plants. Due to high volume manufacturing, there is steady traffic between parts suppliers and assembly sites, which makes it easy to return dunnage back to parts manufacturers for reuse. It is a true closed loop.

Vantage Plastics has been working with the automotive industry since 1996 creating thermoformed plastic dunnage. Sasse says one of the secrets to his company’s success in supplying reusable dunnage solutions to the industry is understanding their needs and being able to deliver thermoformed dunnage using recyclable high-density polypropylene (HDPE) plastic that is customized to the part.

“There are thousands of parts that are in constant need to be received, assembled, moved, and shielded from damage. We work with our partners in the automotive industry to create reusable dunnage that is durable, lightweight, suitable for any environment, and ultimately protective of the part. The high volume of parts, as well as controlled manufacturing environment, really works for reusable dunnage,” he says. “The opportunity now is finding other industries such as the RV and white goods that can adopt a similar model and enjoy the benefits of reusable dunnage.”

Reusable automotive dunnage from Vantage Plastics

Reimagining Dunnage for the Circular Economy

One of the workhorses of the dunnage packaging category are airbags used for load securement within truck, rail and ocean containers. The advantage of these industrial-sized “bubbles” is their light weight, strength, ability to absorb vibrations and impacts, and basically immobilize products during shipping. Reusable dunnage bags have two layers: an inner polyethylene (PE) bladder that is much like a balloon and an outer layer for strength made of either paper, PE or polypropylene (PP).

Reusable load securement airbags from Cargo-Tuff

Early dunnage bags had one-way valves so once the bags were inflated, the air couldn’t escape. This was fine for product protection but there was no way to reuse the bags and thus most were landfilled. Reimaging the bags for reuse required creativity on the part of CargoTuff, a leading supplier of dunnage bags.

“One of the first things we did to enable reusability was to make bags with two-way valves so the bags can be deflated after use and re-inflated for the next trip,” says Helmut Elze, vice president and general manager, Cargo-Tuff. “The outer layer of our reusable bags is PE or PP, materials more amenable to multiple use. Additionally, at the end of life, we can recycle PE or PP together.”

The package is only part of the “reimagining” process, says Elze. Customers also need to be educated on how to reuse dunnage bags. It’s an easier sell to companies with established inter-company shipping and transfers as deflated bags are easy to ship. In addition to the sustainability benefits of reusable dunnage bags, Elze says they save companies a tremendous amount of time and promote workforce safety.

“Dunnage bags are quick to place and inflate in a container and there’s nothing to splinter, nothing to cut or assemble, no pesticides or preservatives in our materials, and thus nothing to hurt workers. When you add in reusability and the option of recycling rather than landfilling used packaging, reusable dunnage bags are very attractive,” Elze says.

Innovative Plastic Dunnage that Supports Reusability

As mentioned earlier, plastic is ideally suited for reusable dunnage. One versatile format is PE foam sold as buns, sheets, and rolls that can be used as dunnage on their own or as a raw material for thermoformers to create custom solutions. PE foam is preferred for dunnage as it can be formed to a specific product’s specifications, it doesn’t splinter or absorb moisture, it’s resistant to oil and UV light, and delivers the Class A surface protection important to makers of automotive parts, large appliances, and other products with vulnerable finishes.

Worldwide Foam is a large supplier of foam buns, sheets, and rolls that continues to innovate within the category. Marketing Director Leon Huang says the company recently launched a new product line called MCP that is a unique micro-cellular, closed-cell, recyclable PP foam that provides a great strength-to-weight performance ratio and elasticity. Additionally, MCP is very fine to the touch and has no chemical residue, odor, or volatile organic compound. It is ideal for a wide variety of dunnage applications for the automotive, RV, consumer goods, medical packaging, sporting equipment, and leisure markets. Like other PP foams, it lends itself as a component within reusable dunnage products.

Reusable PE foam dunnage from Worldwide Foam

Reusable cargo protection from TriEnda

TriEnda is a U.S.-based global manufacturer of thermoformed material handling solutions that continues to push the boundaries of traditional dunnage products like bulkhead spacers, separators, void panels, cover, and side buffers, adjustable void guards, wheel risers, and chocks, as well as plastic pallets. TriEnda Marketing Manager Michala Meyerhofer credits the reusability and recyclability of HDPE plastic dunnage products for the growing demand.

“Plastic dunnage makes more sense in terms of cost, durability, economic impact, ease of sanitizing, being impervious to water, and just the infinite number of shapes and designs we can create. It’s also one of the easiest materials to recycle. At the end of a product’s lifecycle, we simply grind and reuse the material. No water or chemicals used to recycle,” she says. TriEnda offers a buy-back program of its plastic pallets to ensure recycling and discourage landfilling.

TriEnda’s Cargo Protect+ HDPE product line provides superior protection by air, truck, and rail, and have proven to reduce damage by up to 80% while safely maximizing shipment load capacity. To support safe handling, each solution is engineered to protect people. The HDPE does not splinter and TriEnda includes ergonomic handholes to enable fast, safe, and easy loading and thus reduce dock-related injuries. Many of their dunnage solutions are nestable, rackable, and stackable to facilitate cost-effective returns for reuse.

Driving Adoption of Reusable Dunnage

For all of the advantages or reusable dunnage, broad adoption isn’t a done deal. In fact, it will require tremendous effort from both dunnage makers and users to achieve widespread adoption of sustainable solutions. Corplex’s de la Torre says the complexities of companies’ supply chains and ingrained processes can make the shift to reusables particularly challenging.

“With some exceptions, current supply chains offer few points to return the packaging. So adoption of reusable dunnage will require us to reimagine supply chains and logistics processes. Change is difficult and it requires the commitment of entire organizations and also a financial investment. The return on investment is there, but it will take time,” she says.

In the meantime, Corplex has made sustainability and reusability an integral part of its corporate ethos and business strategy. From a packaging design perspective, it looks at each dunnage solution from a “cradle-to-cradle” and preferably mono material perspective. “On the frontend of each project, we look at the application, the material used, how it’s to be engineering, the desired usable life, and recycling options at end of use,” de la Torre explains.

Reusable dunnage from Corplex

One striking example is Corplex’s reusable AkyPak returnable sleevepack containers that fold flat when empty, enabling efficient returns. Filled, 66 boxes fit snugly into a tractor-trailer. Empty, four times the number of boxes fit in the same space, a significant win for logistics and for reducing the carbon footprint. The boxes, which are lightweight, durable, impact and water resistant, and eliminate the need for shrink wrap, have a useful life of up to seven years and are 100 percent recyclable. Customers recover the price of the container in less than 18 months.

Summing up the journey to reusable dunnage, de la Torre, who previously worked with the World Wildlife Federation, says “If you really want to change the world, you have to work for a corporation that’s committed to change. That is how things get done.”